IDENTIFYING UNMARKED SOLDER

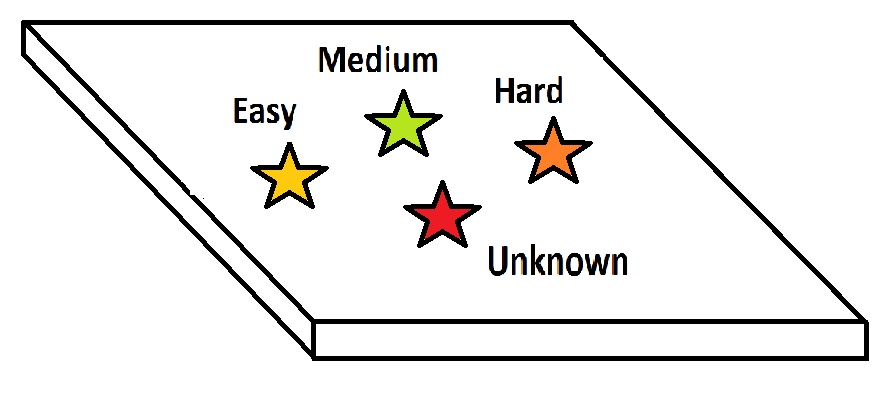

There are plenty of ways to mark your sheet or wire solders, but suppose you forgot to mark them and have a couple that you can't identify. The answer is to compare the melting temperature of the unknowns with that of a known solder. What I do is take a thick scrap of copper or nickel and arrange several solders on it. Ideally, I would have a sample of easy, medium and hard known solders surrounding the unknown solder. Then I heat the plate from the bottom and watch the order in which the solders melt.

-----------------

INEXPENSIVE ELECTRIC WAX PEN

You can make your own wax pen from a small soldering iron plugged into a light dimmer switch for heat control. Both components are easily found at a big hardware store or at Harbor Freight. As an example of the components, see items # 43060 and # 47887

File the tip of the soldering iron into the shape you prefer or even better get a soldering iron with replaceable tips. Then you can make several tip shapes for different tasks. Set the dimmer control just hot enough to melt the wax without producing any smoke.

A tip design that I find ideal for some work is a length of small gauge wire that lets me reach in around the model to melt some wax. The wire is 18ga and about 15mm long. I use Sterling wire to conduct heat easily to the tip, and I silver solder it into a hole on the end of a copper or brass rod that fits into the soldering iron.

Discover New Jewelry Tricks in Brad's "How To" Books

Amazon.com/author/bradfordsmith

Happy hammering,

- Brad

- Log in to post comments